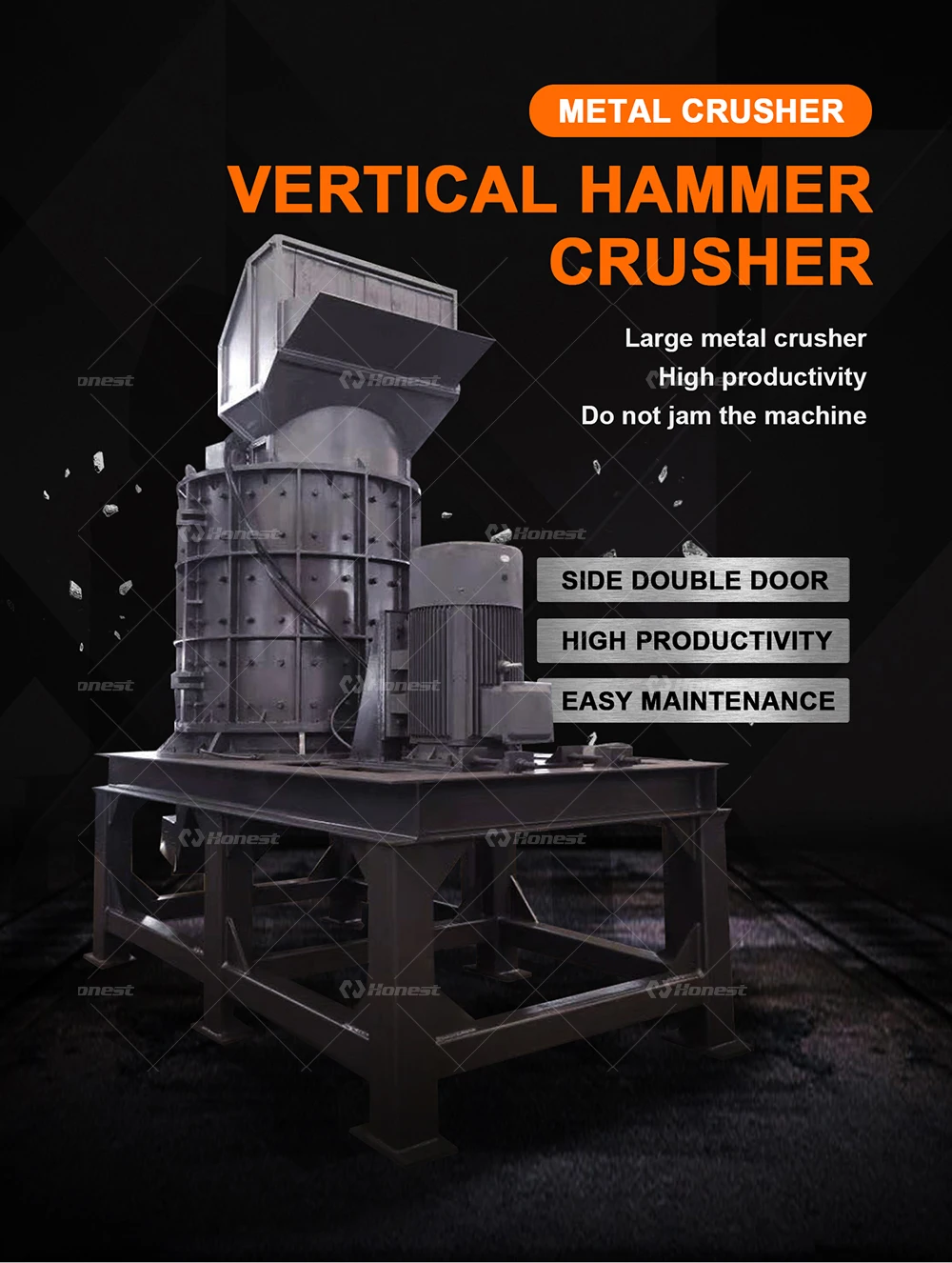

Metal Vertical Hammer Crusher

The HONEST Metal Vertical Hammer Crusher is a compact and highly efficient me...

The HONEST Metal Vertical Hammer Crusher is a compact and highly efficient metal reduction machine designed for fast crushing of light and medium-hard scrap materials. Featuring a vertical crushing chamber, the machine uses gravity-assisted feeding and high-speed hammer impact to quickly break metals into evenly sized particles. Its vertical structure allows materials to move smoothly through the chamber, helping to prevent clogging and ensuring continuous, stable throughput. This crusher is engineered with a precision-balanced rotor that delivers strong impact force while minimizing vibration during operation. The wear-resistant hammer set and reinforced inner liner enhance durability, making the machine suitable for long-term industrial use. Operators can easily adjust the output size to meet different recycling or smelting requirements. The HONEST Vertical Hammer Crusher is ideal for processing aluminum scraps, thin steel pieces, metal shells, cans, electronic light metal parts, and other recyclable metal fragments. Its simple layout, low maintenance needs, and high reliability make it an excellent choice for metal recycling plants, foundries, and pre-crushing production lines. By reducing material volume and improving downstream separation efficiency, it offers a cost-effective solution for modern metal recycling operations.

| Model | ZY1000 | ZY1200 | ZY1500 |

| Capacity(kg/h) | 800-1000 | 1500-2000 | 2000-3000 |

| Power(kw) | 75KW*2 | 90KW*2 | 132KW*2 |

| Spindle speed(rpm) | 650 | 650 | 672 |

| Rotating diameter(mm) | 1000 | 1500 | 1500 |

| Number of hammers | 2pcs | 4pcs | 2pcs |

| Unit weight of hammer head | 20kg | 25kg | 30kg |

| Number of hobs | 36pcs | 36pcs | 36pcs |

| Unit weight of hob | 40kg | 40kg | 42kg |

| Kicking device | Active type | Active type | Active type |

| Power of hydraulic station | 2.2kw | 2.2kw | 2.2kw |

| Hammer head material | High manganese alloy steel | High manganese alloy steel | High manganese alloy steel |

| Equipment weight(t) | 9t | 12t | 18t |

| Equipment size(mm) | 1200*1200*3000 | 1500*1500*3200 | 1800*1800*3500 |

The HONEST Metal Vertical Hammer Crusher is a compact and highly efficient me...

The Plastic Crusher (Knife Type) from HONEST is a high-efficiency crushing ma...

The HONEST Metal Horizontal Hammer Crusher is a robust and high-capacity crus...